Meet us at ANUGA Food Tec 2024

Join us at Anuga FoodTec 2024! OptiCept Technologies is thrilled to be a part of the event, showcasing our innovative PEF technology in Foodtech.

OptiCept has developed a new application area for the company’s technology platforms. The method combines Pulsed Electric Field (PEF) with a vacuum injection for softening fruit or vegetable products (pieces of fruit or vegetables). This new technology can naturally improve the organoleptic properties of products to be even more appreciated by consumers and be very beneficial for the pineapple industry as success with tests on pineapple chunks has prompted the filing of the patent application.

Picture this: you eagerly pick up a pineapple from the grocery store, envisioning sweet and succulent slices to enjoy. However, upon cutting into it, you’re met with disappointment – the pineapple is hard, fibrous, and lacks the juicy sweetness you were hoping for. This scenario is all too common for consumers around the world.

So, why do consumers prefer softer pineapple slices or chunks?

Soft pineapple slices have a more tender and juicy texture, which many people find more enjoyable to eat. Riper pineapples tend to be softer and sweeter.

They are easier to work with, particularly when incorporating them into recipes or adding them to dishes like fruit salads or desserts. They’re easier to cut and manipulate without the risk of being too tough or fibrous.

Softness is often associated with freshness and quality in fruits like pineapple. Consumers may perceive, hence prefer, softer slices as fresher and better tasting than harder ones.

Ultimately, if consumers are not satisfied with the texture of the pineapple slices, they may be less likely to purchase the product again in the future. This can negatively impact the producer’s reputation and long-term success in the market.

The problem with hard pineapples extends beyond mere inconvenience.

The pineapple industry producers grapple with meeting consumer preferences, ensuring product quality, and managing processing difficulties. The texture of pineapples can vary depending on factors such as the variety of pineapple grown, growing conditions, and post-harvest handling practices. Some varieties are naturally firmer than others, regardless of where they are grown.

How pineapples are handled after harvest can affect their texture as well. Proper storage and transportation practices, including temperature control and minimizing physical damage, are crucial for preserving fruit quality. Perfunctory post-harvest handling can lead to firmer pineapples due to dehydration, especially of premature fruits.

Working closely with the pineapple industry regarding increasing juice extraction, led OptiCept into exploring the pineapple processing overall, discovering that hard, white-colored pineapple slices were a problem for some producers. That is how the idea was born.

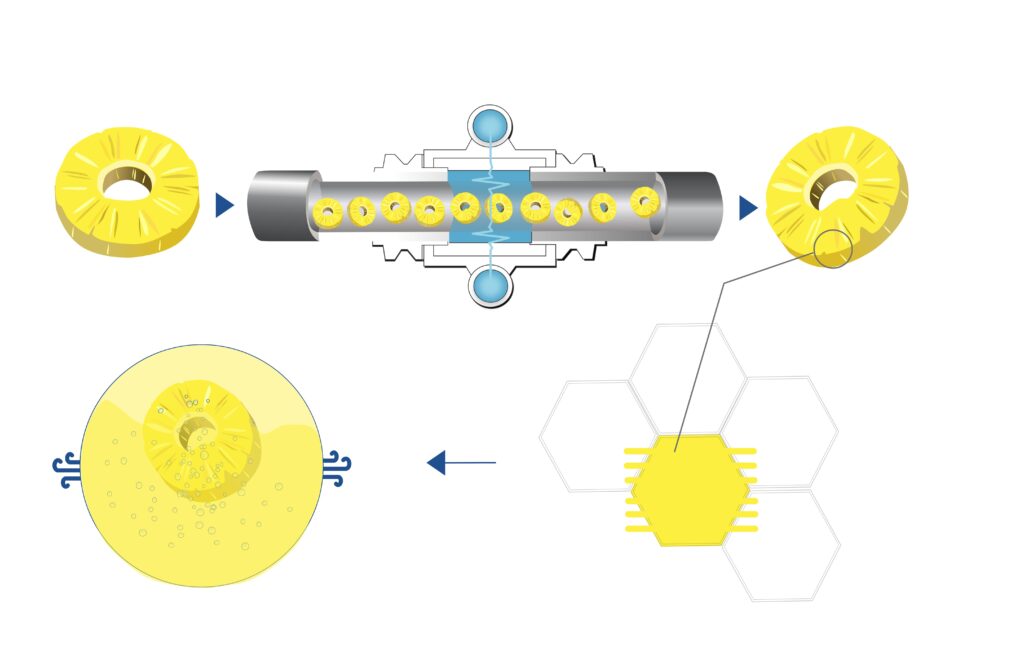

OptiCept has two technological platforms.

OptiCept has developed a patented technology called CEPT (Controlled Environment Pulsed Electric Field Treatment).

Pulsed electric field (PEF) technology is a non-thermal food processing method that uses high-voltage, low-energy electric pulses to disrupt the cell membranes of the treated commodity. The resulting impacts are enhanced mass and material transfers as well as selective deactivation of pathogenic and spoilage microorganisms in the food matrix.

PEF technology also preserves or enhances the original color, flavor, texture, and nutritional values, especially in juice extraction.

Vacuum impregnation technology introduces external liquids into porous structures such as plant tissue. The tissue is immersed in the liquid and subjected to a two-phase pressure change. The liquid infused into the material may have different properties, and VI can thus be used to change the composition of plant tissues.

By combining these two technologies a new application area opened in fruit and vegetable processing. So how does it work?

The method includes a Pulsed Electric Field (PEF) step followed by a vacuum injection step, or the steps separately for softening fruit or vegetable products (pieces of fruit or vegetables), where the fruit or vegetable products are impregnated with fruit or vegetable juice to improve product color and texture. This new technology can naturally improve the organoleptic properties of products to be even more appreciated by consumers due to improved texture, consistency, and color.

With a texture analyzer probe, it’s possible to measure the “softness” of materials, such as pineapple chunks.

The test shows that PEF opens the cells, and the chunks are softer with minimal leakage

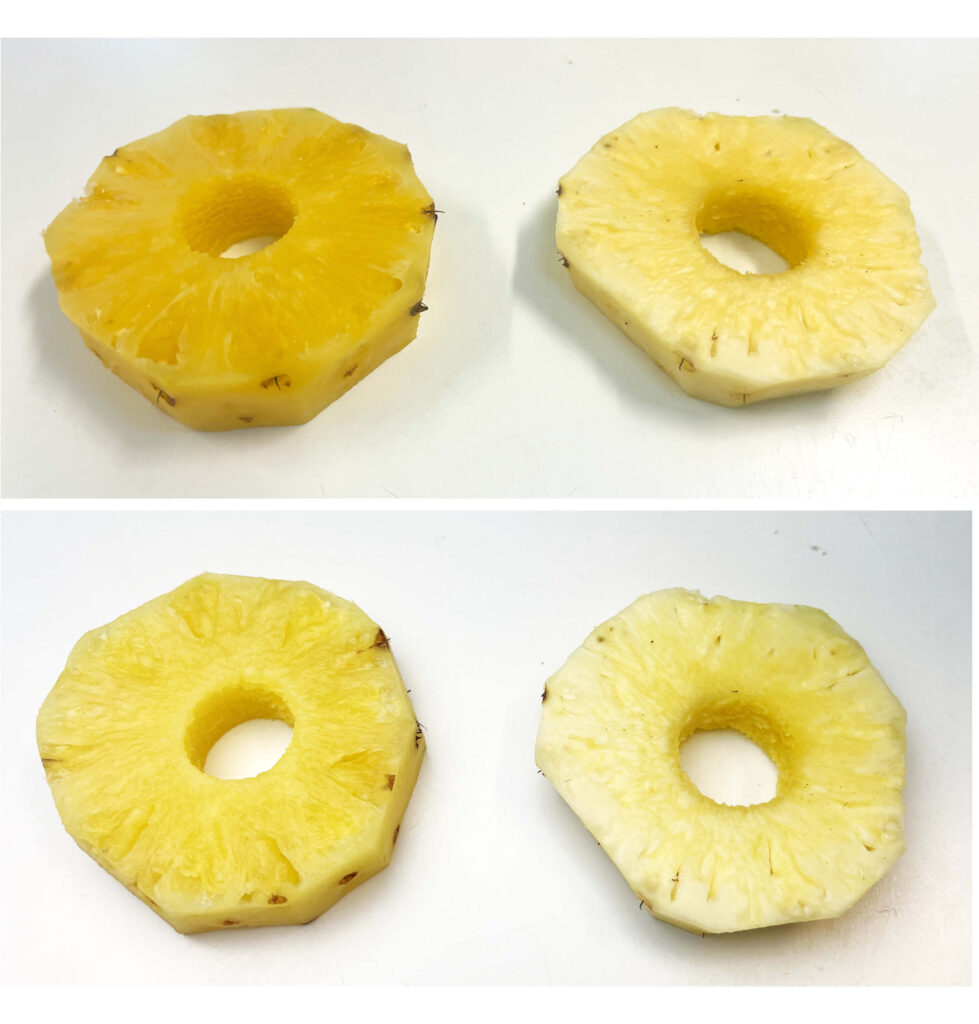

In conclusion, applying PEF alone on pineapple chunks will soften the fruit. Next up, we added a VI treatment to see what effect we could have on coloring

Measuring color intensity or shades can be tricky, as individuals experiences this differently, however the difference is quite clear when putting treated slices next to untreated ones:

The new application area creates new valuable opportunities for the industry. With improved quality, our customers can increase the margins of existing products and create new products for new markets, enabling an expanded market reach.

Pineapples treated with the new technology may gain access to new markets and consumer segments. The ability to offer premium-quality pineapples could open up opportunities for export to regions with high demand for fresh produce.

Softening and enhancing the color of pineapples could lead to greater consumer satisfaction and increased demand for the fruit. Consumers may be more inclined to purchase pineapples that consistently offer superior texture and appearance.

Another benefit for pineapple producers is the competitive advantage. Companies utilizing this technology could gain a competitive edge in the pineapple market by differentiating their products based on superior quality and appearance. This could lead to increased market share and brand loyalty.

Overall, introducing PEF+VI to soften and enhance the color of pineapples has the potential to revolutionize the pineapple industry, driving growth, improving quality, and meeting the evolving demands of consumers and markets.

Lastly, there are many other fruits and vegetables where the same method could be applied, creating the same opportunities across the industry.

We are happy to help you with any questions and thought you might have.

Join us at Anuga FoodTec 2024! OptiCept Technologies is thrilled to be a part of the event, showcasing our innovative PEF technology in Foodtech.

In a world where consumers are increasingly concerned about the quality and freshness of their food, innovative technologies are emerging as key players in meeting these demands. Pulsed Electric Field (PEF) technology is one such innovation.

OptiCept Technologies, together with Canadian partner FPS Food Process Solutions Corp, has successfully completed the verification of its PEF technology for potato processing

OptiCept delivers innovative solutions for Food & Plant Industries to improve quality, performance & reduce waste.

Get the latest news from OptiCept Technologies straight to your inbox