More from less

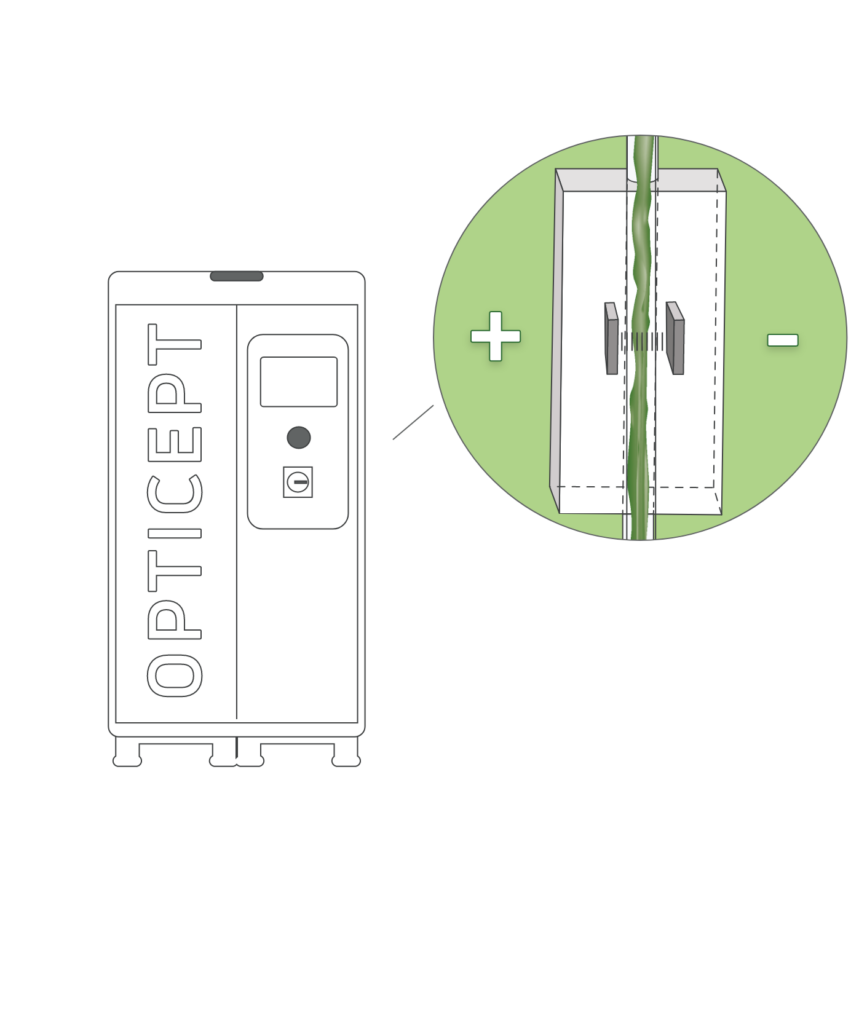

Dematerialization – the art of creating more from less. OptiCept Technologies patented CEPT platform for treatment of food products is based on PEF (pulsed electric field) technology.

Improve food safety, quality, and shelf life, while also reducing energy and resource usage.