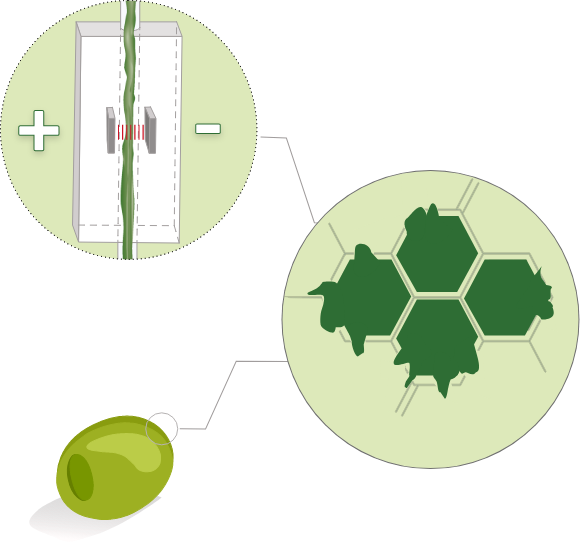

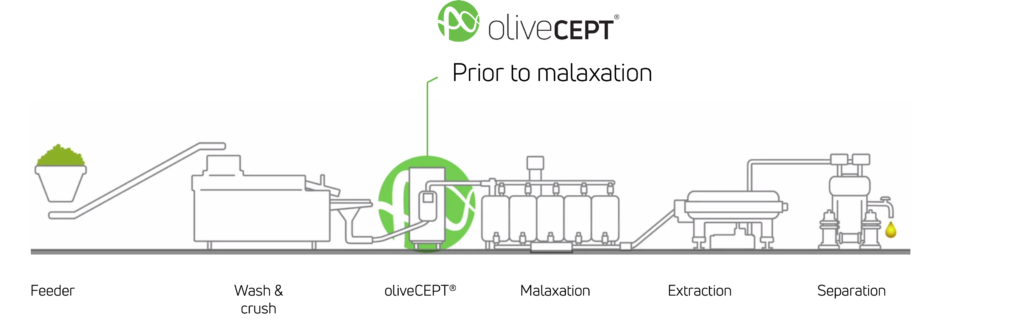

How does PEF enable increased olive oil extraction

PEF enables olive oil producers to extract more oil from each processed olive. How you might ask? In this post, we’ll take a closer look at how pulsed electric field technology impacts the olive oil extraction process.