PEF Technology for Cranberry Juice

Can PEF (pulsed electric field) technology help boost Cranberry juice production? Experimental lab studies show it might have a great impact.

The juiceCEPT® can be applied for these main purposes:

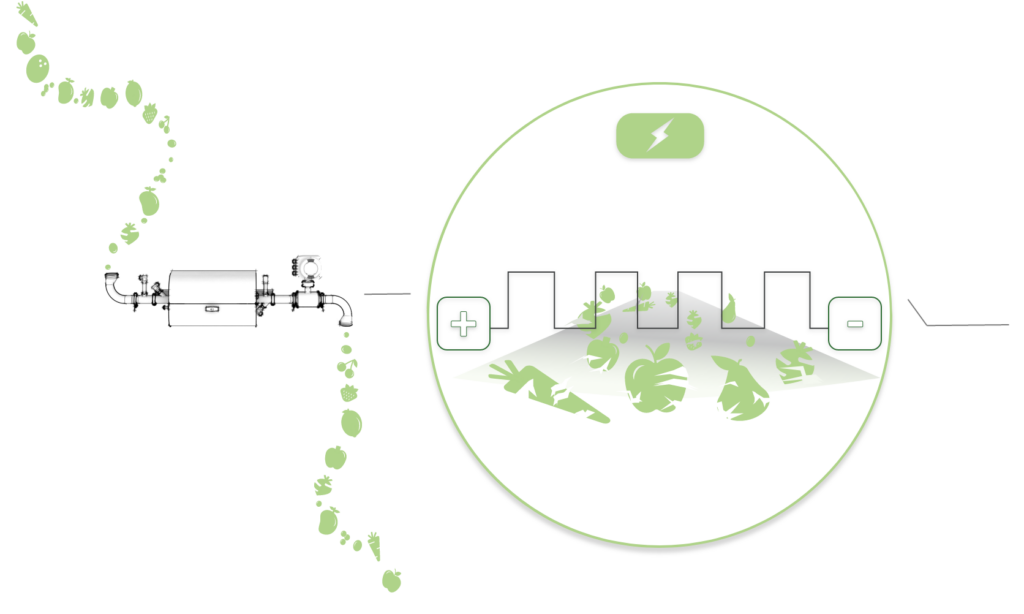

With juiceCEPT® we improve extraction by micro-scale destruction of cell membranes. Boost cellular release of nutrients, enhancing quality substantially. Increase shelf-life by reducing and inactivating microorganisms like yeasts, molds, and bacteria. The machine and technology is easily retrofitted into the existing vegetable and/or fruit juice production process.

Il principio base della tecnologia è l'applicazione di brevi impulsi ad onda quadra di alta tensione che generano campi elettrici molto elevati. A causa dei brevi impulsi di grandezza di microsecondi, il riscaldamento eccessivo e le reazioni elettrolitiche indesiderate sono ridotti al minimo.

Il CEPT platform is a high voltage generator combined con trattamento chambers. I technology ora sta primarily used within food production to increase extraction e extend sustainability. CEPT is based on short-term high voltage pulses (PEF) che inhibits the cell membrane e kill unwanted microorganisms.

Biomass (cells) exposed to high voltage pulses, temporarily (electroporation) or permanently (electric lysis), destabilizes the lipid bilayer e proteins of the cell membranes.

Generates electric fields and electric breakdown.

In basic terms: the electric pulses allows for more juice to be extracted without compromising it’s quality.

We’ve put together an extensive guide comparing other technologies common in the juice industry to clearly show the benefits of juiceCEPT®. Download the guide below, and you’re always welcome to book an introductory meeting with us!

The heat effect of the treatment is low and the heating of the juice is limited to only 1-3° Celsius.

The treatment is continuous and easy to retrofit into existing extraction lines. The technology is energy efficient and barely heat the product, which is otherwise detrimental to sensorial attributes like taste and color

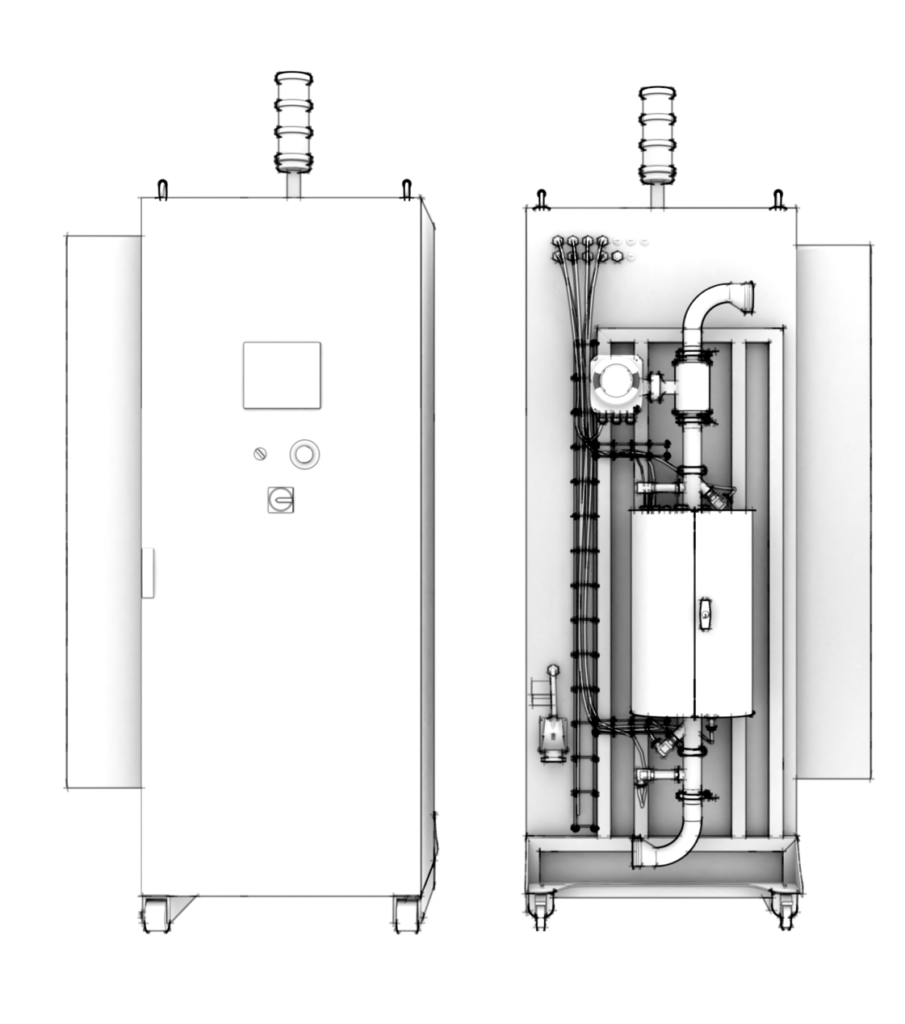

The juiceCEPT® consists of a CEPT v6 PEF high-voltage generator and a cabinet with an optimized booster step. The equipment continuously monitors and logs pressure, temperature before and after the treatment as well as the product flow.

These sensors provide valuable information about the treatment process and allow complete quality assurance and process safety. With the flow sensor, the treatment is only enabled when there is an actual and enough flow through the system. The process connection is stainless steel, food-grade, dairy fittings.

By its activity causing natural cells, ́ electroporation facilitates juice and nutrients extraction thus reducing enzymatic and holding time. Simply feeding the product by a positive pump and controlling the flow by a magnetic flowmeter.

Il juiceCEPT® solution is scalable where an increased number of units will multiply the flow rate with the same number. The juiceCEPT® is operated via controlCEPT, a Siemens-based PLC system, which is prepared for customer-based digital start/stop signals or complete integration to end-users PLC-systems.

Possiamo raddoppiare la vita utile dei succhi freschi spremuti mantenendo freschezza e naturalezza.

The main benefits of applying the technology of juiceCEPT+® are, firstly – an increase in shelf-life by up to 21 days using minimal heat impact that does not damage color, taste and nutritional values. Second, maintained quality in taste, color and nutritional values of bottled juices due to the cold process treatment of juiceCEPT+®.

We offer a very simple yet powerful commercial offers for juice producers looking to extend the shelf-life of high-quality juices. We call it 21-21. Meaning, we guarantee a 21-day shelf-life for only 0,21 Euro per treated liter. Learn more about the concept, let’s meet up!

Migliora l'estrazione mediante la distruzione su microscala delle membrane cellulari della materia prima schiacciata come frutta, bacche e verdure. Aumenta il rilascio cellulare di minerali, vitamine, composti coloranti e altri micronutrienti migliorando notevolmente la qualità.

For the juiceCEPTx® application for increased extraction and improved quality we also offer a very beneficial business model.

Increase juice yield extraction, depending on commodity and production facilities. The price for this is only 0,025 cents per treated kilo, simple! No upfront investment. Pay per treatment.

Treatment of juice with CEPT® technology will keep the temperature below 40°C, and still, achieve food safety, keeps the nutrient content, the natural freshness.

The two methods can also be combined by installing two separate units and treating the juice in two steps during processing.

Il needs e requests della customers have changed throughout the last decades, one della them being a longer shelf-life. Different processes have been established throughout il years to extend il shelf-life della different food products.

HPP and CEPT® may have the same purpose and some producers may actually benefit from HPP rather than CEPT®. However, there are several advantages that only CEPT® can provide by opening up the cell membranes. A couple of differences should be taken into account when comparing these technologies.

Can PEF (pulsed electric field) technology help boost Cranberry juice production? Experimental lab studies show it might have a great impact.

How can PEF technology be implemented in juice production? PEF, or Pulsed Electric Field, is a technology and a non-thermal pasteurization method. It involves applying

OptiCept and Dole join forces to improve juice production efficiency. OptiCept and Dole join forces to improve fruit and vegetable production efficiency. Will explore the potential of the CEPT platform.

OptiCept offre soluzioni innovative per le industrie alimentari e vegetali per migliorare la qualità, le prestazioni e ridurre gli sprechi.

Ricevi le ultime notizie da OptiCept Technologies direttamente nella tua casella di posta