Testimonio del cliente - Moulin de L’Olivette

Conozca cómo la almazara galardonada Moulin D'Olivette en Francia aprovecha el uso de oliveCEPT

For extra virgin olive oil production ripened olives are grinded and the oil is extracted mechanically or chemically. Even though the olive oil industry is a very traditional industry, the development of new technology is needed and highly appreciated.

Extra virgin la extracción del aceite de oliva oil (EVOO) is characterized by its high amount de phenolic compounds. Thus, there is no need for physical or chemical refining. However, la extracción del aceite de oliva oil producers constantly aim to improve el quality de el oil y increase el extracted yield. That ahora está why different technologies have been developed in order to improve both el quality and the yield.

PEF has been known and has been a popular technology within el la extracción del aceite de oliva oil industry. PEF is hereby used to increase el permeability de the cell membranes que leads to easier oil extractability. One de many ventajas de PEF is, that there is no need to heat the product.

When it comes to olive oil production, the first important step is the removal of leaves, since the presence of leaves could change the taste and aroma of the oil. After that, the olives are put in a feeder as a first step in the process line. Here, the taste and aroma can also be affected.

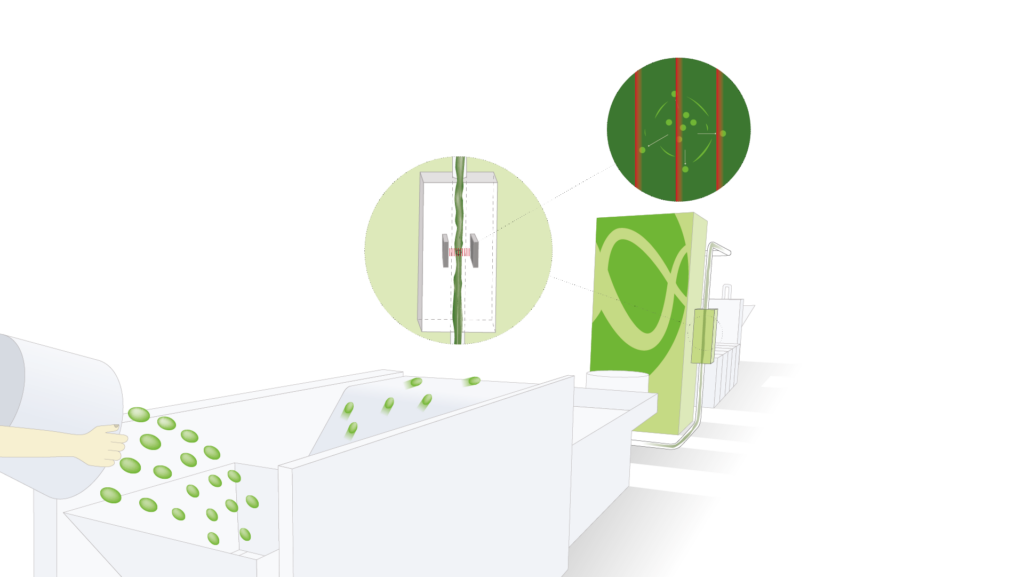

With oliveCEPT®, which is based on PEF, we can improve the organoleptic characteristics such as color, fruitiness, bitterness, and pungency of the olive oil without sacrificing valuable yield. Furthermore, we can minimize the malaxation time since an important preparatory work is already done through the CEPT® treatment. The oliveCEPT® is integrated into the initial process right after the crusher.

El oliveCEPT® deploys a pre-treatment to the olive paste in extra virgin olive oil production that improves both the quality of the product and increases the extracted EVOO yield. The integration of oliveCEPT® in the initial stage of the process right after the crusher offers a number of advantages when it comes to the extracted yield and quality of the final product. oliveCEPT® has proven reliable results on these aspects.

In a traditional olive mill, the olives usually move from washing to crushing to malaxation to centrifugation. The oliveCEPT® machine is installed prior to the malaxation step with the aim to open up the cell membranes of the olives.

With oliveCEPT® the processing temperature and malaxing time can be reduced down to absolutely minimum values which enables real cold milling and a continuous production process. Malaxation time can be reduced substantially from 45 min down to 5 min without affecting the yield negatively. The oliveCEPT® runs with 25 °C process temperature during 25 minutes malaxation. This combination leads to an efficient production with maximum performance and superior olive oil quality.

oliveCEPT® releases more oil at any temperature, which offers the miller flexibility to adjust malaxing time according to the specific characteristics of the local olives and the targeted quality standards of the olive oil produced.

oliveCEPT® is a system that uses pulsed electric fields to boost olive oil production. Processing temperature and malaxing time can be reduced down to absolute minimum values.

OptiCept Technologies patented CEPT® technology consists of a high voltage generator combined with treatment chambers. The chambers increase the shelf-life of juice and increase the amount of olive oil for instance. The streamlined chamber treats the liquid with electrical pulses.

CEPT® can be described as crossing the bio-lab with the electronics lab. Short pulses and high voltage are combined in order to puncture the cell membranes, which leads to increased yield and better quality of the product.

Olive oil is only one example of products that can be treated with CEPT. CEPT® is here used as a pre-treatment to the olive paste, which is based on pulsating electric fields (PEF) that opens the olive cell membranes with short but very powerful electrical pulses. But also treating juice with CEPT® has led to very positive results. Want to know more? Download our Super Juice Guide:

Conozca cómo la almazara galardonada Moulin D'Olivette en Francia aprovecha el uso de oliveCEPT

OptiCept organiza un evento para presentar los resultados del tratamiento PEF en la producción de aceite de oliva

El PEF permite a los productores de aceite de oliva extraer más aceite de cada aceituna procesada. ¿Cómo podrías preguntar? En esta publicación, analizaremos más de cerca cómo la tecnología de campos eléctricos pulsados afecta el proceso de extracción de aceite de oliva.

OptiCept ofrece soluciones innovadoras para las industrias de alimentos y plantas para mejorar la calidad, el rendimiento y reducir los desechos.

Reciba las últimas noticias de OptiCept Technologies directamente en su bandeja de entrada