OptiCept lanzará pruebas de sostenibilidad independientes para flores cortadas

OptiCept lanzará pruebas de sostenibilidad independientes en el Reino Unido para flores cortadas en septiembre.

The unique technology of OptiBoost® brings multiple advantages to the table for the forest industry. Treating cuttings postharvest with vacuum impregnation increases the survival rate of unrooted cuttings and enhances valuable quality characteristics.

All markets have their first movers, the early adopters. In the forest industry and propagation of cuttings, we’ve entered a partnership with one of them.

In late 2022 and early 2023, A global forest company with a base in Chile will start treating Eucalyptus cuttings with the OptiBoost® technology.

The company is one of the world’s largest pulp and paper companies and employs 17 000 people. Activities include forestry, pulp, paper, and paper products.

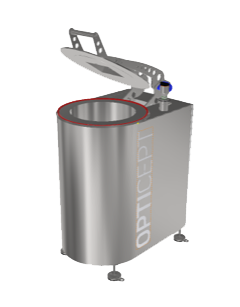

The unique and patented OptiBoost technology is based on vacuum impregnation or infusion and designed for treating cut flowers or in this case, cuttings.

The new OptiBoost® application SAGA is optimized for the treatment of cuttings. The application has shown many positive effects, including improved survival in planting.

Below, we explore the technology a bit more and the impact on the forest industry and the propagation of cuttings.

Growing trees from seeds are often precarious. Cuttings on the other hand provide many advantages for growers, and many have the ambition to transition more to cultivation through cuttings.

With good reason, the advantages are many. With cuttings, a faster start to cultivation can be achieved, as in fact, it is already a small plant. Compared to seeds, cuttings, thus, have a shorter growth period, which generally means that you can harvest faster. The problem then is the survival rate. The OptiBoost® for cuttings technology increases the survival rate of unrooted cuttings.

Average Survival/Loss for control plants.

Average Yield Increase

Average Survival/Loss for plants treated with OptiBoost. Planted in the same environment as the control plants.

The technology is based on vacuum impregnation. Pressure change causes the evacuation of air from the leaf air spaces. Pressure is gradually modified to allow a nano-based nutrient solution to enter the specific fraction of the tissue. Pressure parameters are meticulously designed and controlled to achieve impregnation. In the second phase, pressure is gradually modified to allow the nano-based nutrient solution to enter the specific fraction of the tissue. The cuttings are boosted with nutrients, making them more robust and significantly increasing the survival rate of the cuttings.

The unit is not overwhelming when it comes to size. SAGA, named after the Norse mythology goddess, measures around 1000 mm x 500 mm and weighs about 230 kg. A compact unit, however, with a high capacity that can treat up to 35 000 cuttings in an hour. One single treatment takes only 30 seconds.

The treatment of cuttings has a majority of positive effects, including strengthening the growth, robustness, and root system of cuttings, which improves the survival of transplanting and faster growth.

Being a first mover brings a lot of advantages. Your business receives early access to an advantageous new product and technology. Get in touch now to discover how this could be beneficial to your company.

Obtenga más información sobre el mundo de la tecnología de campos eléctricos pulsados con cámara. Conozca casos de clientes, artículos, vídeos y noticias.

OptiCept lanzará pruebas de sostenibilidad independientes en el Reino Unido para flores cortadas en septiembre.

Con OptiBoost para flores cortadas, una tienda de comestibles sueca logró aumentar las ventas en un 15 % y reducir el desperdicio en un 25 %.

OptiCept ofrece soluciones innovadoras para las industrias de alimentos y plantas para mejorar la calidad, el rendimiento y reducir los desechos.

Reciba las últimas noticias de OptiCept Technologies directamente en su bandeja de entrada