How long is fresh juice really fresh?

Efforts to increase shelf life often mean compromising the quality of the juice. So how do you solve this dilemma? With juiceCEPT+

The needs and requests of customers have changed throughout the last decades, one of them being longer shelf-life. Different processes have been established throughout the years to extend the shelf-life of different food products.

Lower prize – quicker pace: Advances in technology have made interconnection between different countries and different branches possible. However, globalization and other factors have also led to a competitive world and the need for many manufacturers to produce longer lasting products. It has also led to a need to produce more in the same time span.

The needs and requests of customers have changed throughout the last decades, one of them being a longer shelf-life. Different processes have been established throughout the years to extend the shelf-life of different food products. Discover even more details about the CEPT technology for juice production.

HPP and CEPT® may have the same purpose and some producers may actually benefit from HPP rather than CEPT®. However, there are several advantages that only CEPT® can provide by opening up the cell membranes. A couple of differences should be taken into account when comparing these technologies.

HPP stands for “High-Pressure Processing”. The shelf-life of the product in question is being prolonged by putting high pressure on the sealed product. It is a process in which the sensorial and nutritional properties of food are being maintained.

CEPT® stands for “Closed Environment Pulsating electrical field Treatment” and is based on short-term high voltage pulses. Hereby the shelf-life of the product is also prolonged – However not through affecting the sealed product, but through modifying the basic product in an earlier stage.

The average investment and operation costs differ significantly with HPP being much more costly.

HPP treatment can prolong the shelf life of juices significantly. However, regardless of what method is used to preserve nutrients in a juice, degradation of vitamin C will happen over time. After 3 weeks the concentration of C vitamins falls to 50% in different juices. Thus, there is really no point in having a shelf life longer than 3 weeks if you are looking to offer high-quality juice. The juice producer that offers valuable juice with high quality is the one that is the winner in the long run.

HPP

juiceCEPT®

The technology has proven very effective for the treatment of juices. Treatment of juice with CEPT® technology keeps the temperature below 40°C, achieves food safety, and keeps the natural product fresh.

“The technology has proven very effective for the treatment of juices. Treatment of juice with CEPT® technology keeps the temperature below 40°C, achieves food safety, and keeps the natural product fresh.”

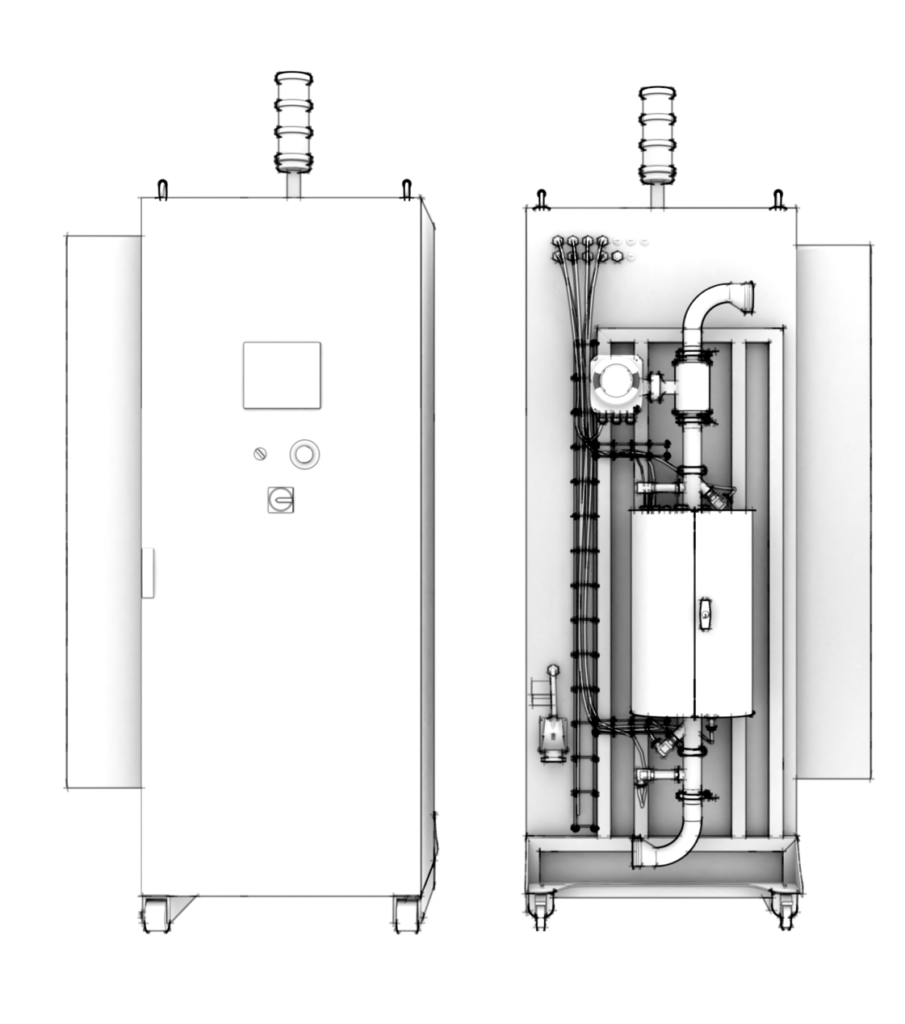

OptiCEPT Technologies patented CEPT® technology consists of a high voltage generator combined with treatment chambers. The chambers increase the shelf-life of juice and increase the amount of olive oil for instance. The streamlined chamber treats the liquid with electrical pulses.

CEPT® can be described as crossing the bio-lab with the electronics lab. Short pulses and high voltage are combined in order to puncture the cell membranes, which leads to increased yield and better quality of the product.

One example of products that can be treated with CEPT® is olive oil. CEPT® is here used as a pre-treatment to the olive paste, which is based on pulsating electric fields (PEF) that opens the olive cell membranes with short but very powerful electrical pulses.

Also treating juice with CEPT® has led to very positive results. Want to know more? Download our SuperJuice Guide!

Global distribution often means challenges when it comes to shelf-life. Extending shelf-life often means pasteurization – giving the juice a longer life span but also destroying much of its rich content. The antioxidants and vitamins are degraded during processing and pasteurization. Treating juice with juiceCEPT® shows outstanding results. CEPT® is a patented technology developed by the Swedish company OptiCept Technologies®. CEPT® stands for Closed Environment Pulsed Electric Field Treatment. It is a method developed to process biomass such as food and other products. CEPT® is a sustainable and eco-friendly method since it reduces organic waste, extends shelf-life and enhances and preserves the quality of the product in question. The technology has proven very effective for the treatment of juices. The juiceCEPT® deploys a technology for juice production that improves the yield and the quality of an extracted juice from fruits, berries and vegetables. The treatment is continuous and easy to retrofit into existing juices’ extraction lines.

Get further insights into the world of CEPT® and Vacuum Impregnation. Learn from customer cases, articles, videos, and news.

Efforts to increase shelf life often mean compromising the quality of the juice. So how do you solve this dilemma? With juiceCEPT+

In the video series “juice of the week” we explore the impact of CEPT on various commodities. This week we take a look at beetroots.